Ed Harris: Loading Cast Bullets In the 9mm Luger/Parabellum.

It’s been too long since Ed Harris has graced our presence. He’s back, though, with an article about shooting cast bullets in 9mm — and, of course, with related stories about his days doing just that at Ruger. Enjoy!

Tales from the Back Creek Diary:

Loading Cast Bullets In the 9mm Luger/Parabellum

by Ed Harris, Gerrardstown, WV

Lately, with ammo supplies in retail stores either drying up entirely, or becoming frightfully more expensive, combined with widespread fears and speculation of whether imports of Russian ammo and primers may be cut off, MANY people have been asking whether they could successfully load cast bullets in 9mm for practice ammo. Until recently my advice was that reloading 9mm ammo wasn’t cost-effective, compared to “readily available and cheap” surplus ammo. That is no longer true… So, when times get tough, it is a simple matter of reloading practice ammo or risking using up your precious stash of factory defense loads. The good news is that you can reload 9mm successfully. Here is how!

A Dillon RL550B was set up to throw 3.6 grs. of Bullseye which we loaded with a 124-gr. truncated cone bevel-plainbased bullet of shape similar to the H&G #7. Bullets dropped from molds at .358 and were loaded as-cast and unsized. Once-fired commercial brass was reloaded using Federal 200 “small rifle and magnum pistol” primers because they were “hard” like military 9mm primers and we wanted to be sure the guns would set them off reliably.

A very important factor when loading cast bullets in small autopistol cases, especially 9mm, is to have a lube bleed hole in seater and crimp dies, so that bullet lubricant buildup cannot cause an increase in seating depth, which results in a dangerous increase in chamber pressure. www.hollowpointmold.com can drill a 1/16″ bleed hole in the Dillon or RCBS seater dies. If you are loading thousands of rounds. I recommend that you do so!

Paying strict attention to seating depth, proper crimp and testing for “bullet push,” no more than 0.005″ shortening of cartridge OAL after 5 secs. at 50 pounds compression pushing against your bathroom scale, is very important. This should be a routine test precaution when setting up the loading machine and is essential to be repeated whenever you change lots of brass or bullets!

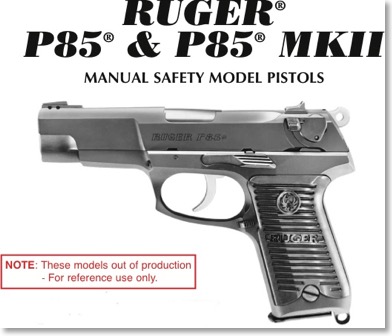

(If you are a firearm manufacturer wanting the equivalent of 9mm “proof” ammo to run “accelerated endurance tests” by firing 188 proof loads in the new design Ruger pistol you are trying to destroy, without having to dip into the limited supply of very expensive “real” proof loads needed for testing the production guns you are selling, all you need to do is take standard GI Ball M882, crack the asphalt bullet sealant with your seating die in your reloading press and reseat the bullet 1/16th inch deeper, for +12 to 15,000 psi~ ! PLEASE! —-DON’T DO THIS AT HOME!!!!) (Editor’s note: seriously, don’t try this. Ed got away with it because he’s a professional who at the time was working in controlled conditions with appropriate safety protocols in place. This information presented for entertainment purposes only!)

I don’t know how many rounds we loaded in that setup, but we were buying case lots of Bullseye, four 8-lb. kegs at a whack, and primers by the skid, loading and shooting several 5-gallon buckets of test ammo every week. We had one guy who did nothing but cast bullets for 8 hours a day, and another who loaded the ammo to feed the trigger pullers who fired a 5000-round endurance test on a random gun selected every day for about six months solid. So, do the math….

- Posted by Grant Cunningham

- On May 12, 2014